Support Structures for 3D Printed Models

2021-09-23

When 3D Printing models, support is indispensable. Without support, those suspended or tilted models will not be printed. Therefore, this is an unavoidable troublesome link.First, when support is needed When the model has suspension or bridge structure, there is nothing to hold underneath, then support structure is needed, but not all suspension needs support.

If the vertical Angle of a hover tilt is less than 45 degrees, the hover can be printed without support. The horizontal skew that the 3D printer moves between the connected layers is very small (hardly noticeable). Thus, one layer is not completely superimposed on the previous layer, but rather superimposed on a small offset. This enables the printer to produce suspended objects that do not tilt vertically too much, and 45 degrees is generally considered a critical Angle.This is best illustrated with the letters Y and T. The two protrusions in the letter Y have an Angle of less than 45 degrees relative to the vertical and do not require support, as does the letter T.

Two, the shortcomings of the support structure

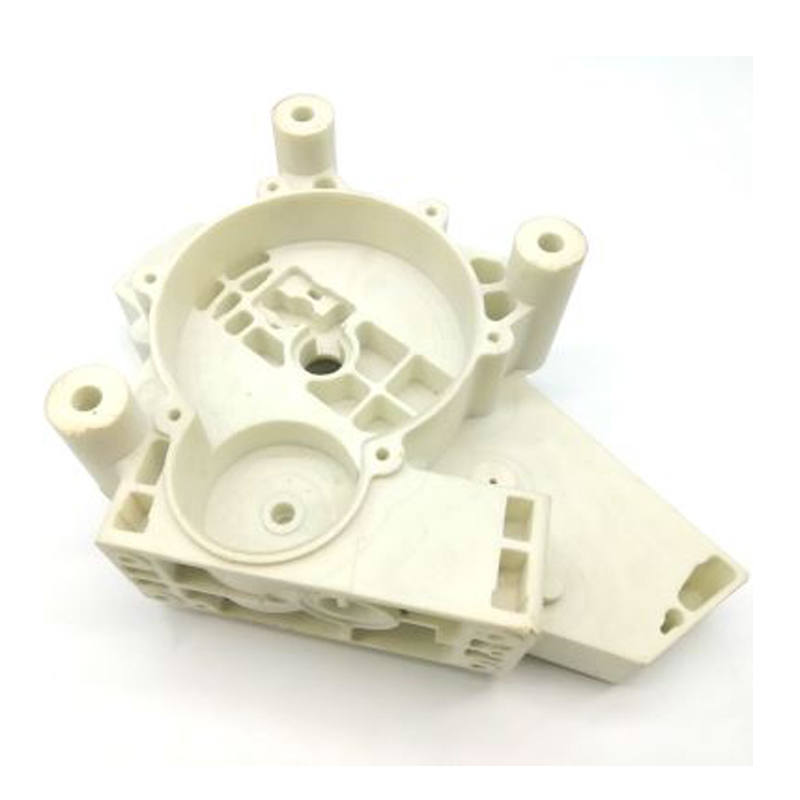

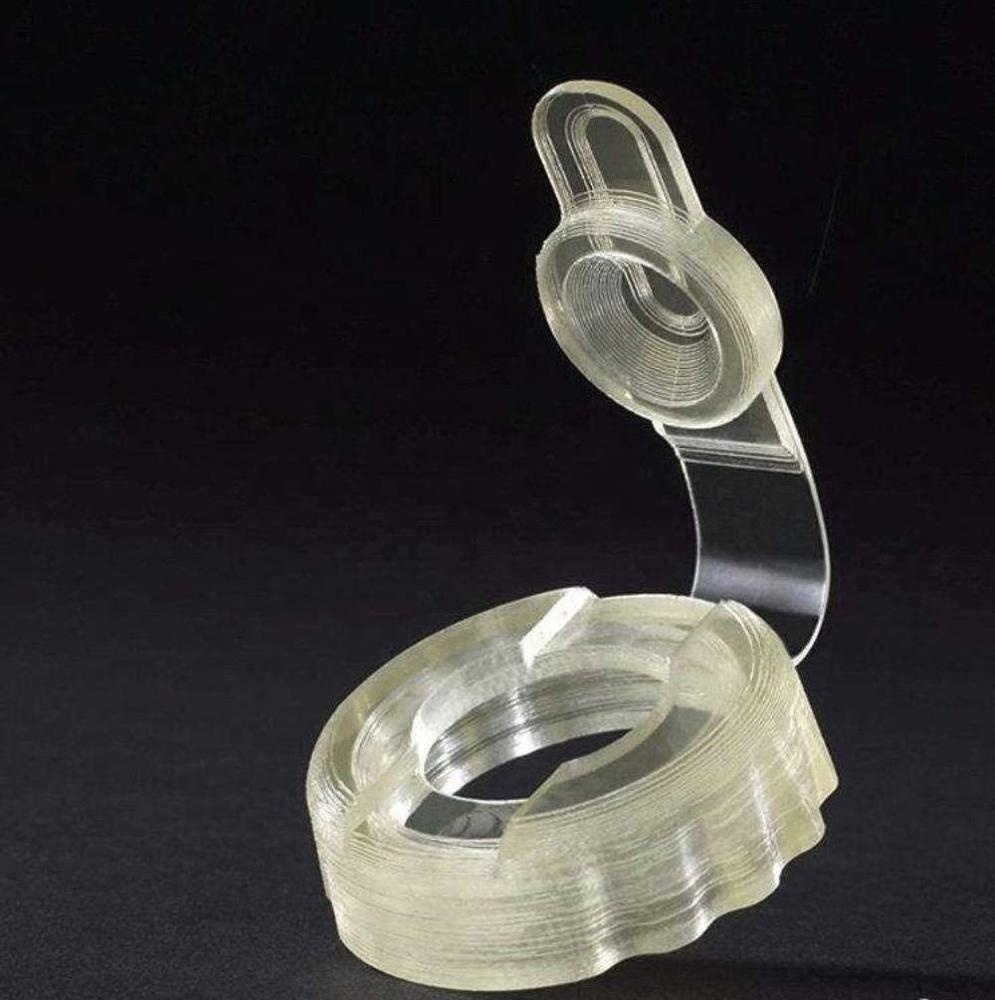

The disadvantages of support structure have also been discussed in detail in the last period, which can be moved: When 3D printing models, the disadvantages of adding 3D printing support, here we briefly talk about! 3D-printed support structures significantly increase the cost and time of the model. Supporting structures consume materials, which are then removed and discarded. Therefore, every time a support structure is added to 3D printing, it increases the cost of the model. Additional post-treatment work, such as removal of supports. The support structure is connected and inserted into the surface of the model. If the 3D support is not carefully removed, it may leave imperfections on the surface of the model. In the worst case, part of the model may break along with the supporting structure. All in all, the use of support structures also has obvious drawbacks. Use support structures sparingly and only add support when necessary. Three, the type of support Tree support: A tree is a treelike structure used to support dangling parts of a model. This type of 3D-printed support is only attached to a few position points suspended in the air.

Tree supports have the advantage of being easier to remove without destroying too much of the overhanging underside. But be aware that it is only suitable for non-flat suspensions, such as the tip of the nose, fingertips or arch. Tree supports do not provide sufficient stability for plane suspensions. Linear/bellows support: a common support type in 3D printing. This type of support consists of vertical columns that are connected to the entire suspension. Almost every suspended and span bridge can use this support. But it is more difficult to dismantle and may cause damage to the surface of the model.

Four, remove the support First, take a look at the support structure, where there is no cover and try to break the support with your fingers. As gently as possible. If done correctly, most of the support should come off very easily. Use a tool to cut off some corner supports. There's a lot of debate about what works best. Ability to use needle-nosed pliers, scraper or chisel. Naturally, it can be used in combination. When using a knife or scraper, heat the model or blade moderately. This makes the supporting structure easier to remove. You can use a small butane spray gun, but make sure you don't damage the model. Many people do not recommend using a carving knife because it is very sharp and dangerous. Sandpaper is also a good tool.

Fifth, chamfering Another way to eliminate supporting structures is by chamfering. Chamfering is a clever way to turn an otherwise annoying hover into a safe one at an Angle of less than 45 degrees. Similarly, if there are holes in the model, you can convert them into teardrop-shaped chamfering holes. In most cases, it does not affect the overall aesthetic of the model. But it can reduce the need for 3D-printed support structures to print models. In short, support structures are unavoidable in many cases. However, it is necessary to ensure the stability of the supporting structure as far as possible without wasting too much material, which is easy to remove and does not damage the model surface.

The above is about how to use the support structure of the 3D printing model to be appropriate and save money. Our company first has Product Development, Mold Maker, Rapid Prototype, Plastic Mould, 3D Print, And Plastic Injection Molding, please consult us.